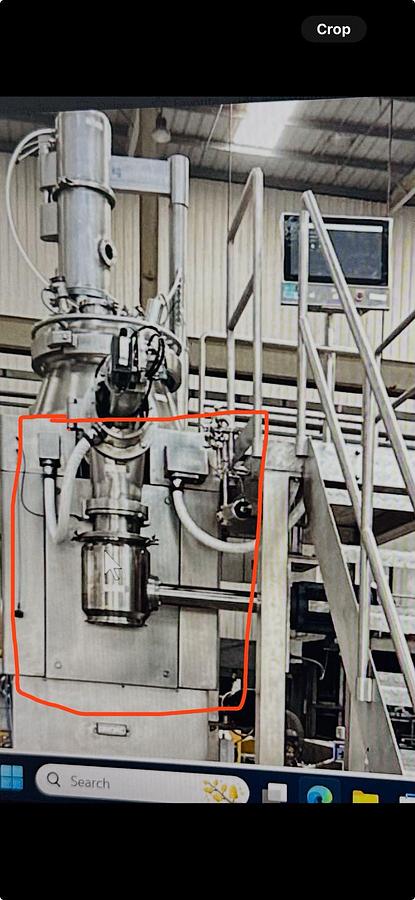

Unused ACG Pharma Technologies Stainless Steel High Shear Mixer/Granulator, Model HSM 150

Unused ACG Pharma Technologies Stainless Steel High Shear Mixer/Granulator, Model HSM 150

Contact us for price

Location:Toronto, Canada

Description

1 Unused ACG Pharma Technologies Stainless Steel High Shear Mixer/Granulator, Model HSM 150. Machine was purchased in 2024 and never used and is still in the original packaging from the OEM. Machine is CSA and ULC compliant and comes with IQ/OQ documentation. Includes Unused Quadro Wet Mill, Model U20 (see bottom of page).

Features:

· 12 bar explosion containment

· capable of handling the following processes:

· Mixing of fine powders which are suitable in their characteristics for the use in a high shear mixing

· •Wet granulation of fine powders with a binder solution.

· configured for both aqueous (water based) and organic solvent-based processes

Product Process: During the process the powdery raw material is combined with a binder solution into a high-quality wet granule. By using a specially designed impeller on the bottom of the product bowl and a chopper in its side wall a controlled multi directional product movement is achieved. After a freely adjustable pre-mix phase for the powders a binder solution is automatically added to produce the actual granule.

Product bowl. The product bowl is of conically shape to support the equal mixing and granulation of product. The transition between the bottom section and the product bowl side walls are rounded to optimize the process efficiency and avoid dead spots. It is manufactured as a 12-bar explosion-pressure shock resistant construction. Made from high tensile 318 (1.4462) duplex stainless steel. All inner surfaces are mirror polished to a max. surface roughness of Ra <0.5 μm.

Three (3) arm impeller consisting of Z-shaped impeller arms. Outer section of the impeller arms in a forward angled design. This design provides additional rotary movement to the product during granulation and avoids the possible build up of dead zones at high filling volumes. Angled product contact surfaces for best possible product pick up and distribution during the mixing and granulation process. Machined impeller arms made from 316 (1.4401) stainless steel with process optimised product expansion areas for maximum performance and reduced energy consumption. Central impeller hub prepared for removal by the optional impeller crane or lifting by the optional impeller lifting device. Compressed air purged impeller seals to prevent dust agglomerations between the impeller hub and the product bowl bottom. Complete with multi zone purge air distribution plate, compressed air distribution manifold, 0.2 μm air filter and air flow meter. Indication of measured values on HMI with alarm display and machine emergency stop if shut off limit is reached.

Multi blade chopper for breaking up product lumps during the granulation process. Allows to set up straight chopper blades onto the chopper shaft. A total of eight (8) chopper blades are included. Consisting of:

· Eight (8) straight chopper blades. The cutting edge of the chopper blade is sharpened for optimised process and energy efficiency.

· Corresponding number of chopper blade spacer inserts.

· Compressed air purged impeller seals to prevent dust agglomerations between the impeller hub and the product bowl bottom. Complete with multi zone purge air distribution plate, compressed air distribution manifold, 0.2 μm air filter and air flow meter. Indication of measured values on HMI with alarm display and machine emergency stop if shut off limit is reached.

The complete chopper drivetrain of the HSM is designed for the operation in a non explosion proof production environment. Consisting of:

· VFD controlled electric motor.

· Electric motor with integrated cooling fan and direct flanged chopper shaft.

· All required sensors to monitor and control the operating conditions of the drive train during production as required by the ATEX guideline in explosion proof execution.

Impeller drive train in non-explosion proof design

The complete impeller drive train of the HSM is designed for the operation in a non explosion proof production environment. Consisting of:

· VFD controlled electric motor for freely adjustable impeller speeds.

· Electric motor with integrated cooling fan and direct flanged gear box.

The ACG X·ONE COMMAND process control system is the next generation state of the art control system fully compliant with FDA GAMP5 and CFR21 Part.11 requirements. Industrial PC based control system with ALLEN BRADLEY or SIEMENS Programmable Logic Controller (PLC). PEPPERL+FUCHS VisuNet visualization with a 19" touch screen as standard, designed and optimized for the use in the pharmaceutical industry. Mounted to the Multi-Function-Column and suitable for the use in zone 2/22 environments. Different installation options, zone 1/21 approved visualization system or keyboard are available as options. The HMI VisuNet EDGE enclosure was specifically designed for manufacturing environments where dust, water and other undesirable materials might accumulate. The enclosure construction with angled surfaces provides wash down capabilities with proper drainage to guarantee GMP compliant cleaning. The zenon software solution by COPADATA guarantees the compliance with international regulations. It offers Out-Of-The-Box GMP compliant automation through configurable pre-validated software modules for functions such as:

· Recipe management and storage including recipe version / revision control

· Audit-trails

· Alarm management

· Archiving of historical data and review

· User Administration including password aging, auto lockout, min. length and multi password control

· System security

· Reporting (selectable reporting function e.g. batch reports, recipes, alarms and trends)

· Historian SQL server:

· Unlimited number of archives and unlimited number of freely selectable variables per archive

· Parallel working archives

· Different archive types in parallel

· Time stamping in milliseconds

· Full redundancy

· High performance from proprietary binary data format

· Integrated with zenon data analyzer

· zenon data analyzer for central data storage including:

· Analyzing of historical data and alarm reports

· Real-time and historical data

· Over seventy (70) pre-configured report templates

· Automated distribution and storage of reports (Network connection required)

Spraying. Comes with 50L – Non Jacket - PU Wheel – Manual Ball Valve - Pneumatic Stirrer, WATSON MARLOW closed coupled peristaltic pump for the supply of spray liquid to the spray nozzle(s) including:

· Pump head design: single head with spring-loaded liquid tube rollers.

· Drive set up: Single gearbox drive with variable speed control.

· Remote control allowing the speed of the pump to be adjusted on the HMI.

· Display of alarms on HMI.

· One (1) set of tubes for: Spray liquid (including suction line), atomizing air and control air.

Specifications

| Manufacturer | ACG Pharma Technologies |

| Model | HSM X-ONETM |

| Year | 2024 |

| Condition | Used |

| Stock Number | 275 |

Disclaimer

The Equipment Kings, Inc. (“TEK”) makes reasonable efforts to provide accurate information and descriptions of the Equipment; however, TEK makes no representations or warranties, express or implied, as to the accuracy, completeness, condition, authenticity, provenance, attribution, genuineness, or value of the Equipment. All Equipment is sold on an AS-IS, WHERE-IS basis.