Unused Automatic Tablet Packaging Line from Aesus Packaging Systems and NJM Packaging Inc.

Unused Automatic Tablet Packaging Line from Aesus Packaging Systems and NJM Packaging Inc.

Contact us for price

Location:Toronto, Canada

Description

UNUSED AUTOMATIC TABLET/CAPSULE PACKAGING LINE

1 New AesSORT 200 Bottle Unscrambler – Fully Automatic “Hook and Belt” Bottle Unscrambler. Fully automatic bottle-feeding machine. LEFT to RIGHT Flow Configuration. Bottle range from 0” to 4” diameter and from 0” to 10” tall. Enclosed frame with safety hinges on all doors. Large 35 Cubic Feet hopper. Machine can handle clear and opaque bottles. Machine can handle round, oval and square plastic containers. Independent manual belts adjustment with pneumatic hook system. Dial indicators on mechanical adjustments for simplified changeovers. Fully adjustable motor speed, controlled in HMI. Pneumatic air gauges to control hook motion. Dedicated snap-in change parts for drum disk. One set included with machine. PLC: Allen Bradley MicroLogix 1400. HMI screen: Panelview Plus Compact T6, 5.5-inch, color. Air Release Valve with low pressure switch. Machine voltage: 208V 1Ph 60Hz. Feeding Drum 48" Change part. Ionized Air Rinse Station. Includes vacuum. CSA Electrical Approval / Certification (Canadian Standards Association) UL recognized

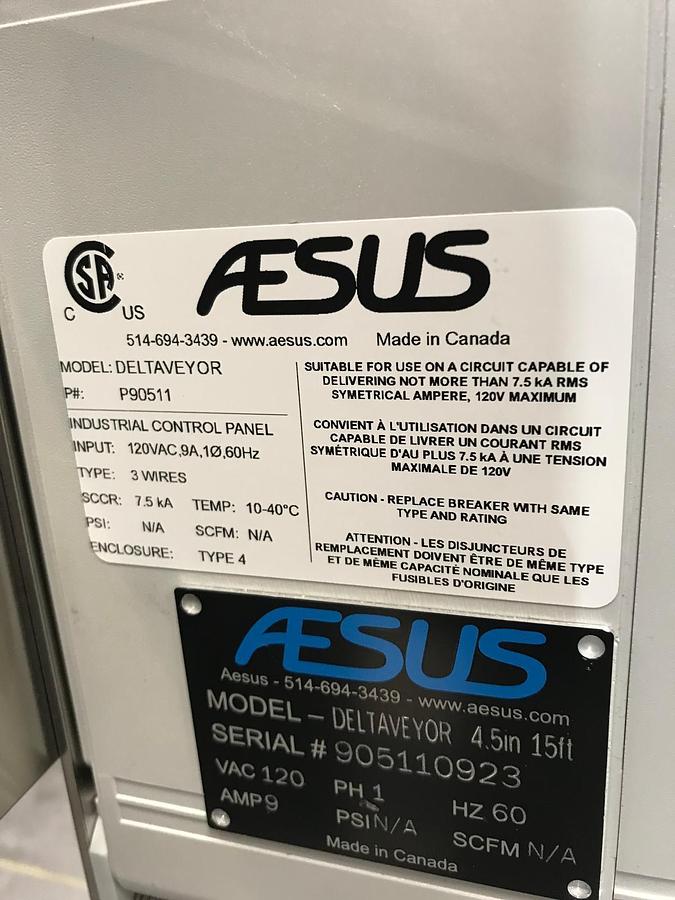

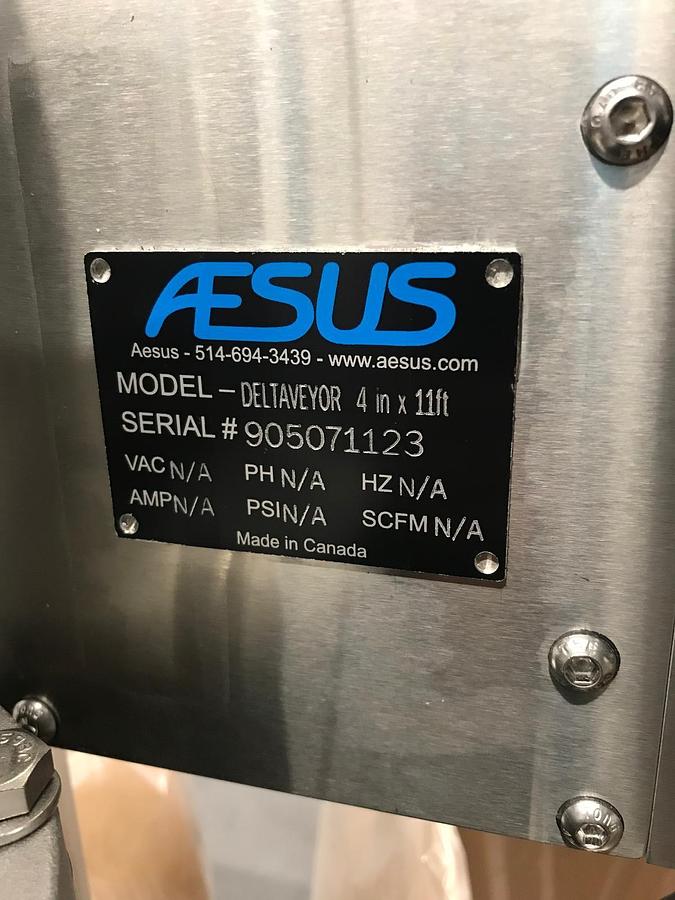

1 New 15 Ft DELTAVEYOR Raised Bed Stainless Steel 4" Tabletop Conveyor. 12 Gauge Stainless steel. Threaded feet for height adjustment. 2” high raised bed for easy access for cleaning beneath. Low friction table top flex chain 4’’wide. Adjustable guides and guide rails. CSA Electrical Approval / Certification (Canadian Standards Association) UL recognized. Lexan Conveyor Covers (minimum 1.2M (4 ft)

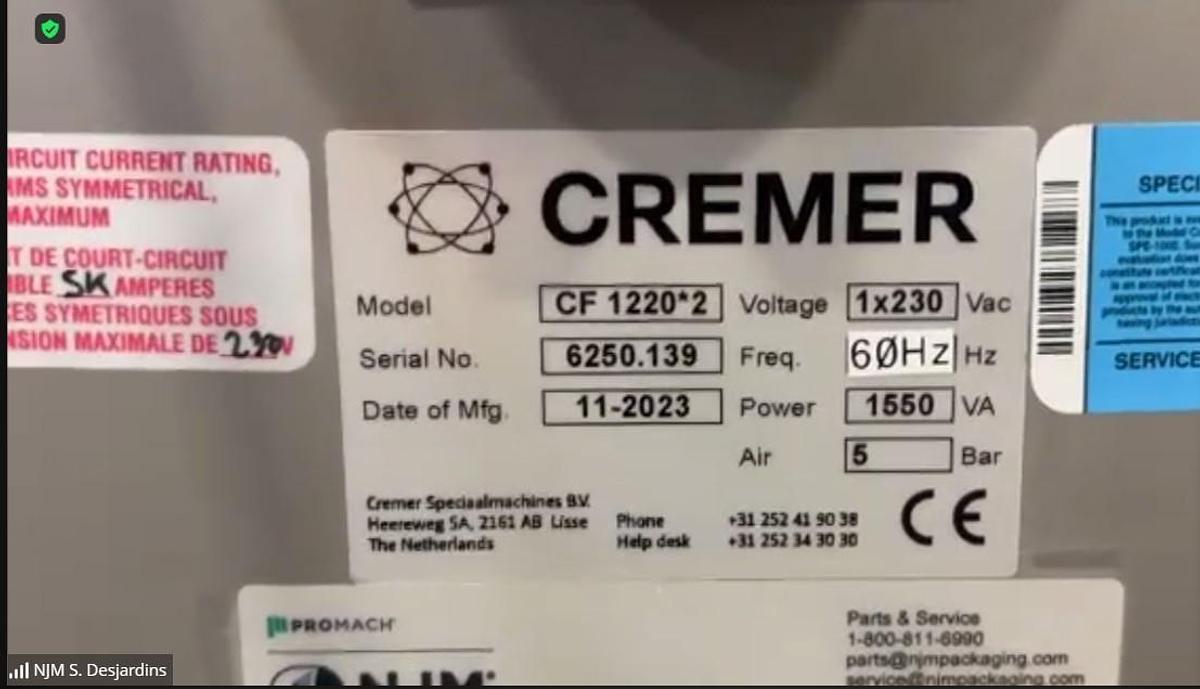

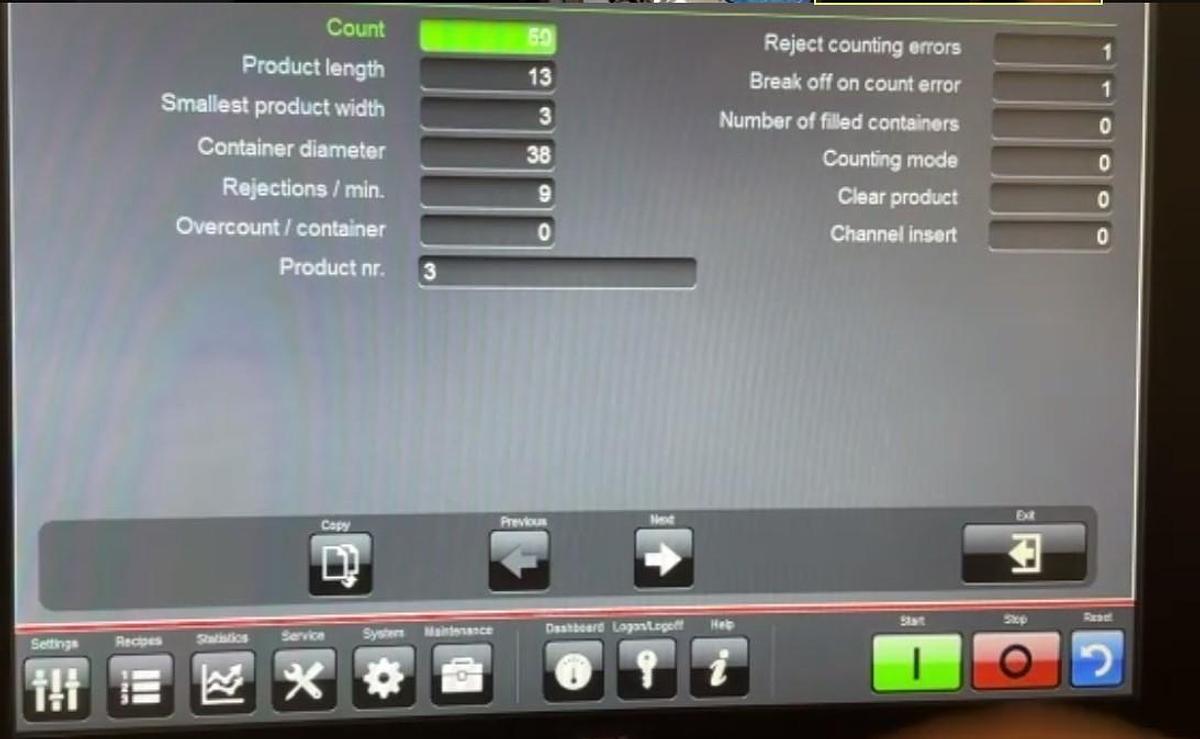

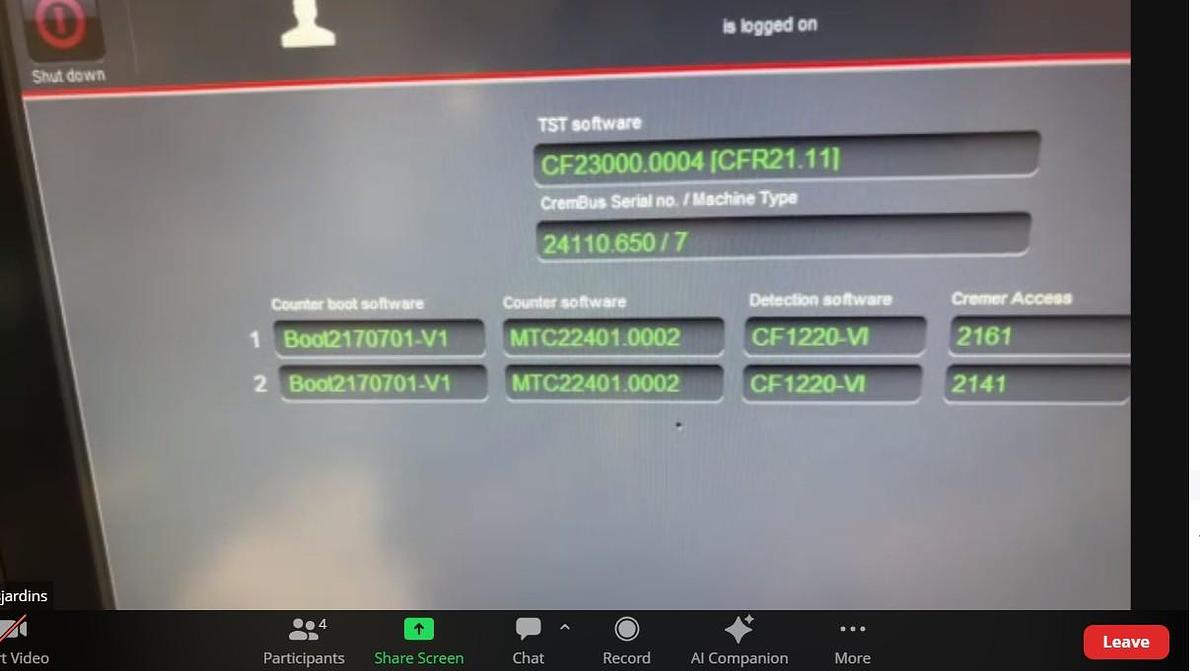

1 New Cremer CF1220D Double Tablet Counter: Up to 100 BPM.

Reference tablet: Round, biconvex, coated ø10,1x4,8mm

Reference container: 100ml bottle ø47,5x76,3 with ø31 neck opening

CREMER GENERAL CF1220D SPECIFICATIONS:

PRODUCT LENGTH RANGE: 2 mm to 30 mm.

PRODUCT WIDTH RANGE: 2 mm to 20 mm.

BOTTLE HEIGHT RANGE: 40 mm to 200 mm.

BOTTLE DIAMETER RANGE: 20 mm 100 mm.

Standard basic machine including two counting heads mounted on one support frame

Each counting head consisting of:

• 30 liters Stainless steel hopper with adjustable outlet gate to control product flow

• Low level sensor in product hopper

• Vibratory outlet plates under the hopper, with small holes to remove dust and dust extraction connections.

• Two independent vibratory plates with 12 V-shaped channels designed to create gap between each product allowing accurate counting.

Counting unit consisting of 12 channels, in which the products will be counted free fall

• Additional channel insert

• Pneumatic memory flaps operated by individual two-stroke air cylinders

• Motorized height adjustment

• Stainless steel outlet funnels with preparation to receive an acrylic nozzle

Equipment on the support frame consisting of:

• One (1) double sanitary conveyor for container filling (4.1 meters)

• Infeed divider and outfeed collector

• Two (2) pneumatic indexing system to stop containers for filling, including central adjustment positioning guide for quick and accurate change-over, without the use of tools

• Two (2) combined verification laser sensor for bottle fallen/upside down and bottle switch in the indexing station (not suitable for transparent bottles)

• Two (2) rejecting system for the removal of miscounted container

• Three (3) back-up switches for automatic start and stop of the indexing system

• Touch screen master terminal

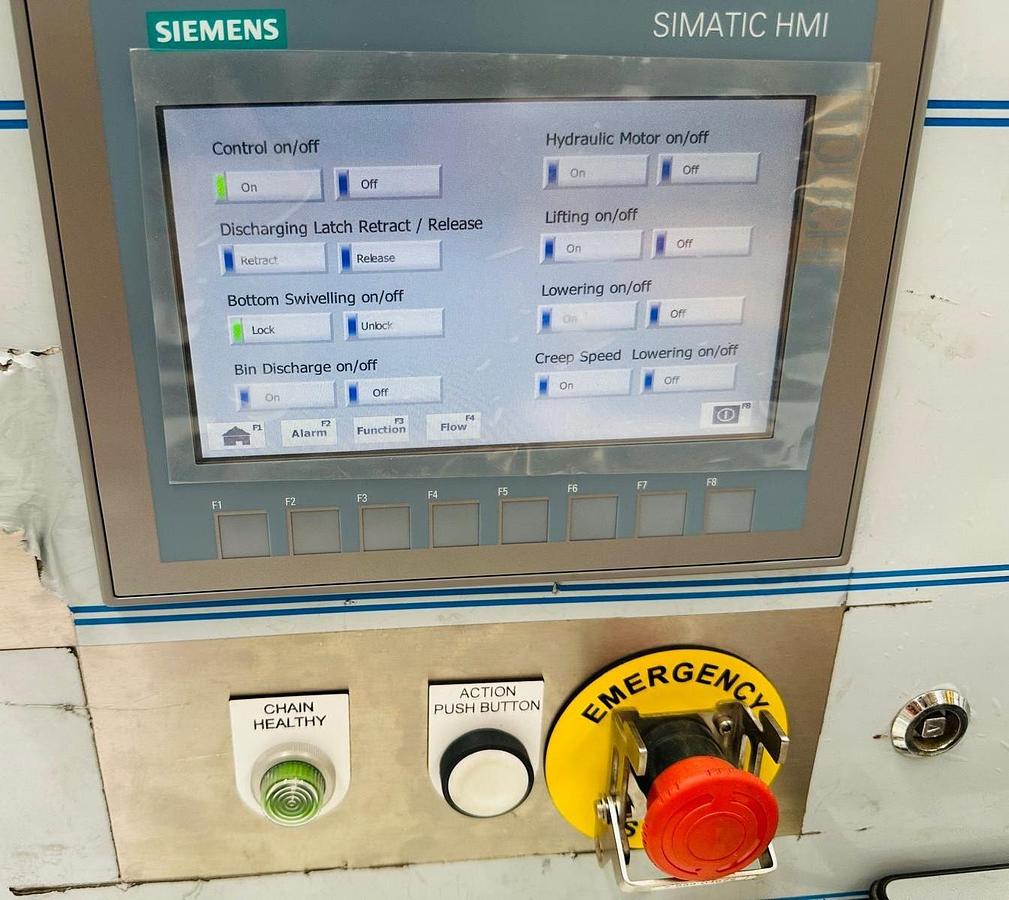

• Emergency stop switch

• Low air pressure control sensors

• Status lamp pole

• One (1) set of two polycarbonate container nozzles

• Set of 2 dust extraction terminal with 3 connections

• Set of 2 dust extraction nozzles for container

• One (1) hard copy + one (1) USB of operating manual

• Wooden crate for CF-1220D counter and conveyor

Voltage: 208 V / 60 Hz / 1 Ph / 6.5 Amp

Air: 6 SCFM at 90 PSI

CSA Certification

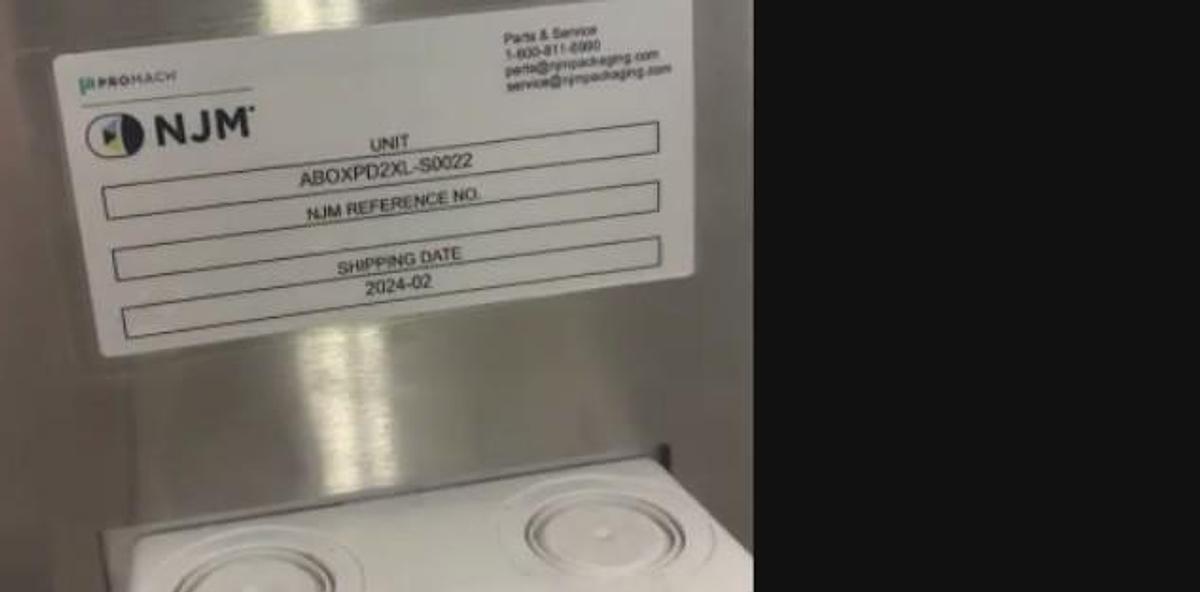

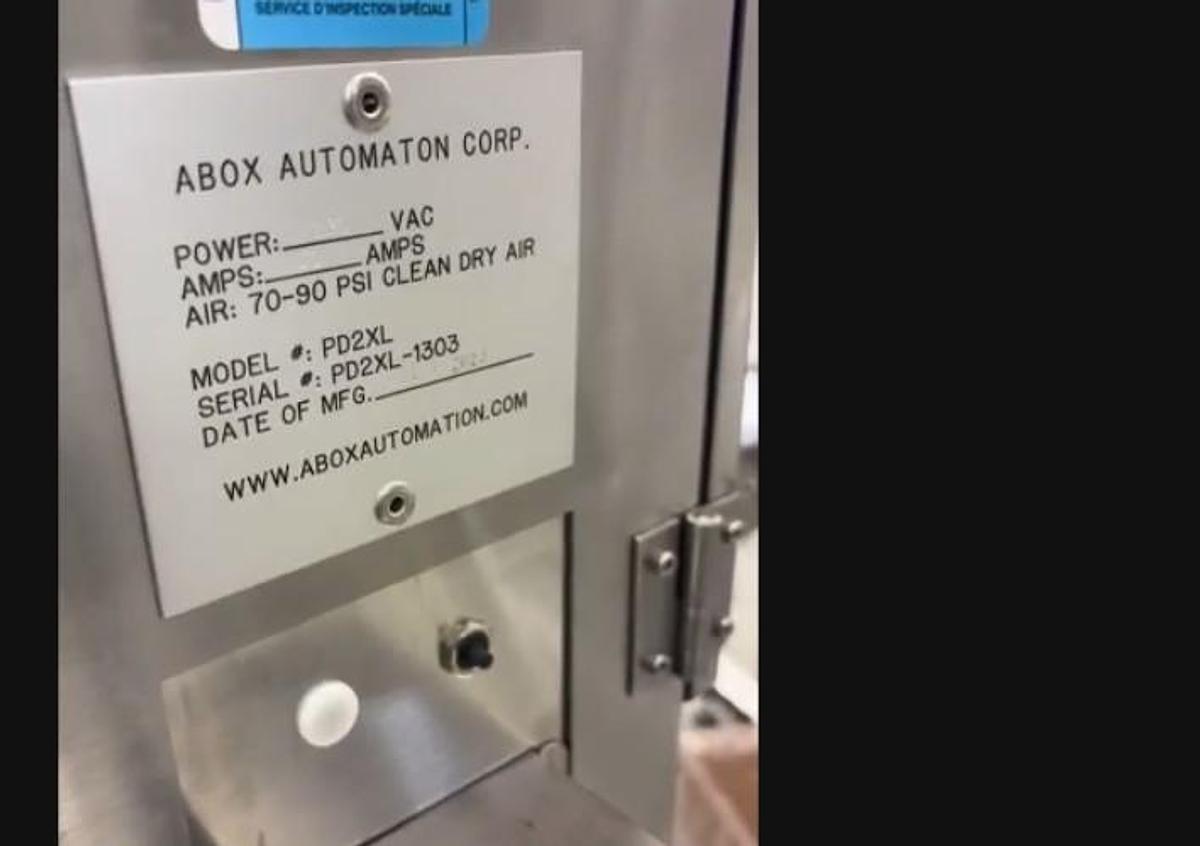

1 New Abox PD2XL Pouch Desiccant Inserter - OUTPUT: Up to 100 BPM

ABOX PD2XL POUCH DESICCANT DISPENSER:

• Slim-line Guillotine knife assembly with through hardened Stainless-Steel blades, is used to cut material.

• Pneumatically actuated.

• Removable knife cartridge for quick blade changes.

• Panasonic touch screen HMI.

• Dual track drive belts for maximum accuracy.

• Track drive is driven by dual steeper motors.

• Traction feed is pneumatically pre-loaded.

• Safety inter-lock system. (Must shut down air to open door)

• Quick change exit chute and in-feed guide assemblies are available for different pouch sizes.

• All Stainless-steel covers and hardware.

• Exit slide chute for precise placement of pouch.

• All Aluminum components will be clear Anodized.

• Out of material sensor. (This sensor will detect if machine is out of material.)

• Jam eye sensor. (This sensor will shut down machine if material is not sensed exiting machine after cut.)

Base Plate:

• The Pouch Inserter and Unwind Stand will be mounted onto a Base Plate to maintain accurate alignment.

• The Base Plate is made out of aluminum with a clear anodized finish.

Unwind Stand:

• Motorized dancer unwind.

• DC Motor will be enclosed within a column, along with a DC Drive controller.

• Dancer arm will control tension by creating a slack loop.

• Adapters can be made to fit different core diameters.

• Speed can be controlled via the controller on the fly.

• Unwind is capable of supporting a roll with an O.D. of 20” and weight of up to 60lbs.

• Aluminum base plate has a clear anodized finish.

• All Stainless Steel Shafts & Hardware

Mobile Stand:

• The Pouch Inserter and Unwind Stand on a Base Plate will be mounted onto a Mobile Stand.

• Clear anodized aluminum columns which slide within each other, are mounted on a mobile base with caster wheels and leveling feet.

• A column-enclosed motor incrementally adjusts height on demand via a membrane keypad.

• Allows for greatest flexibility and easy drop-in installation of the Pouch Inserter at any point on a packaging line.

Pneumatic Gating Bottle Indexing System.

• Will gate each bottle beneath the exit point of the dispensing head to accurately insert a processed pouch into each bottle.

• Will be mounted to the Desiccant Inserter base plate and is modular with the machine.

• Adjustable Sensors & Gate Pneumatic Cylinders.

• Pneumatic Solenoid is integrated to work in sync with the Pouch Inserter.

Laser Bottle Detection Sensors:

• Required to detect Amber, Glass and other Reflective type bottles.

• (2) Bottle sensors per machine.

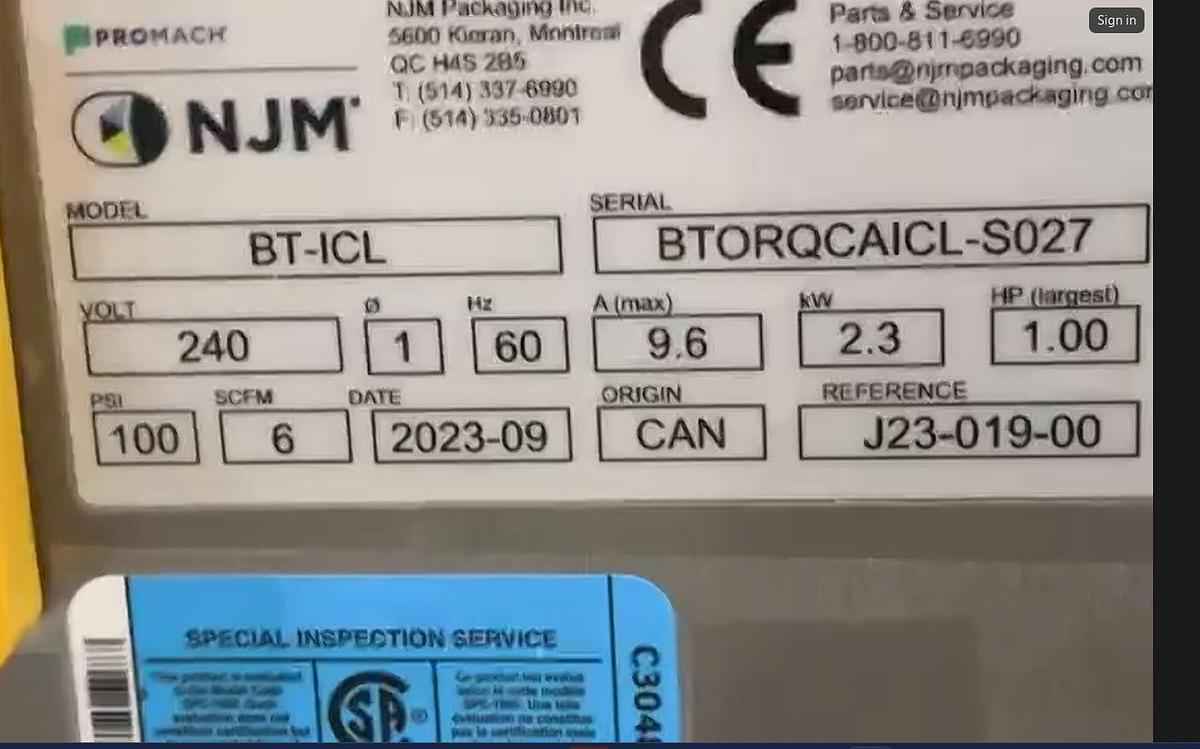

1 New Beltorque® CAPPER LITE (BT-ICL) WITH CAP ELEVATOR – Up to 100bpm.

The beltorque® BT-ICL is a unique, continuous motion, in-line capper that applies screw caps to containers using belts. Unlike traditional disc cappers, the beltorque® extends the duration of contact between the cap and cap belts over a distance of 4” (100mm) per station. The beltorque® technology includes a patented system that synchronizes the linear displacement speed of the container and the rotating speed of the cap as the cap stops turning after tightening.

• Stainless steel chassis

• First station (screwing): pair of belts on a spring-loaded assembly for placing and screwing cap on container

• Second station (tightening): pair of belts on a spring-loaded assembly for application of final torque

• Skewed cap detection between screwing and tightening stations (reject system not included)

• Active assistant system for screwing station to eliminate skewed caps

• Passive overhead pressure plate for tightening station

• Container gripper belts with E-Z lift

• Single point adjustment for the torque setting by air regulator

• All routine adjustments are recordable by the use of counters and graduated scales and do not require tools

• Machine orientation: product flow left to right when viewed from operator side of machine

• Minimum container pitch: 4.5" (114 mm)

• 1 HP (745 Watts) AC motor

• Clear lexan guard including removable and hinged front doors with safety interlocks

• Inlet air regulator with gage

• Low air pressure sensor

• Pneumatic soft start-up and lockable shut off valve

• One (1) illuminated emergency stop button

Specifications:

• Cap diameter 0.78" (20 mm) – 2.75" (70 mm)

• Container width 0.78" (20 mm) – 6.69" (170 mm)

• Container height 2" (50 mm) – 12" (305 mm)

• Manual machine height adjustment

• Allen Bradley Micro 850 PLC

• Allen Bradley PanelView 800 4-inch (100mm) color touchscreen HMI (English language)

• Brushless motor driven cap elevator/orienter including 5 cu.ft. (140 liter) hopper (for caps OD from 24 mm to 75 mm) including:

o Stainless steel construction

o Cleated belt for cap transport and air jet for cap transfer to cap chute

o Manual cleats spacing adjustment for cap diameter

o Lockable hinged door under hopper to quickly remove caps remaining in hopper at a change-over

o Hinged cover on hopper

• Standard cap chute including level sensors to control cap elevator/orienter feed. Width adjustment mechanically auto-set by installation of cap pickup change part for quick and easy adjustment free of cap jams.

• Dual Separating Wheels with discharge bottle backup sensor

• One (1) dedicated set of cap change parts (pickup, tunnel and assistant plate) for cap up to 75 mm outside diameter (inclusively)

• One (1) hard copy + one (1) USB Flash Drive of operating manual (English language)

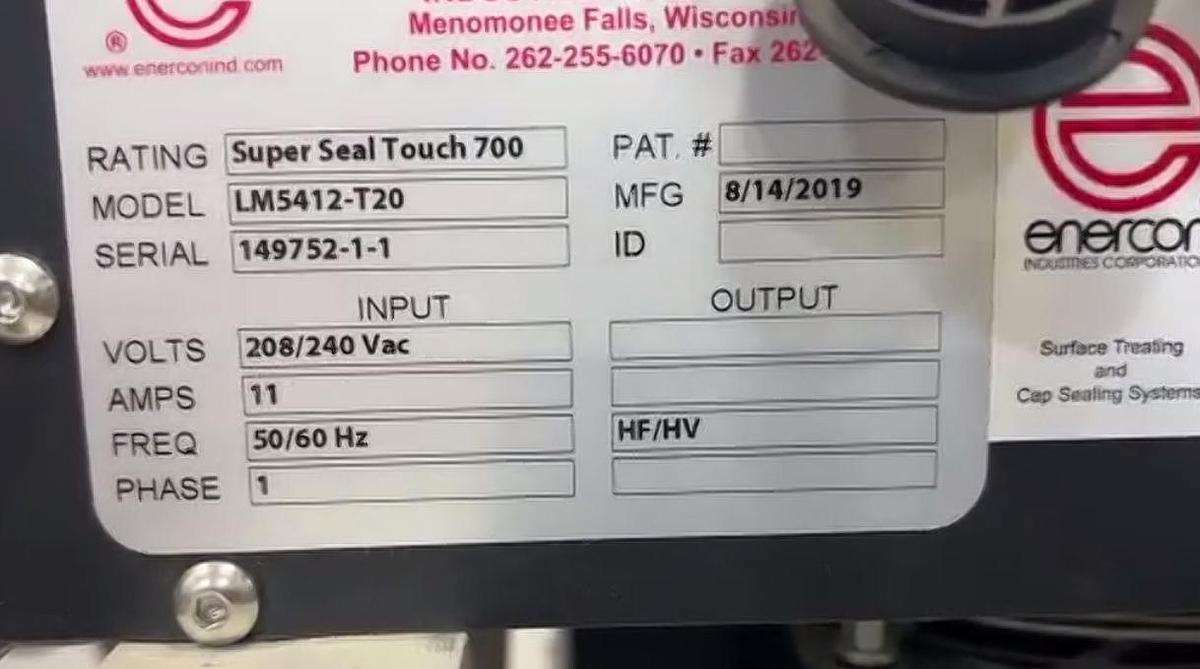

Voltage: 200-240 V / 50-60 Hz / 1 Ph / 11 Amp Air: 1 SCFM at 100 PSI (28.3 l/min. at 6.9 bars)

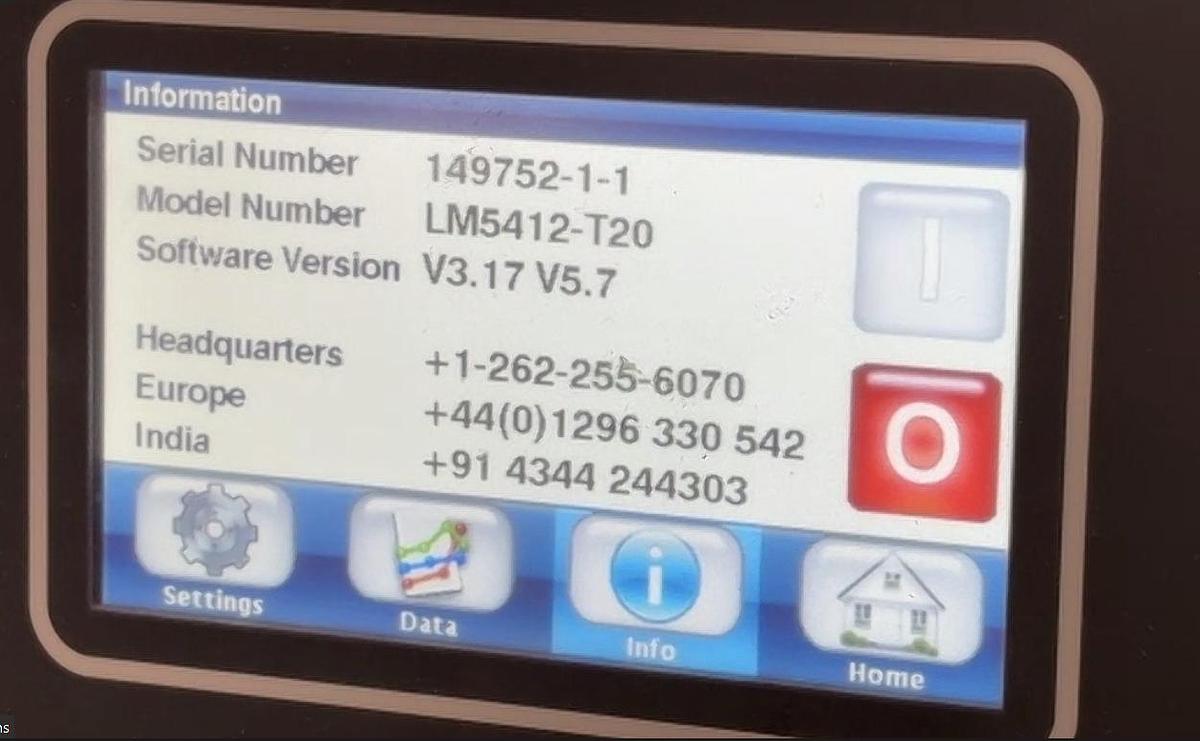

1 New Enercon Super Seal Touch 700 Induction Sealer for 33mm, 38mm 53mm caps - Up to 100 BPM.

Enercon’s Super Seal™ Touch provides enhanced productivity, easy setup, more control & all the sealing power you need to achieve a perfect seal. Take advantage of recipe management, operator lockout.

• Intuitive touch screen makes setup & operation simple

• Supervisory password protection with operator lockout

• Recipe management, remote start/stop and remote power control

• Stainless steel enclosure

• Universal input voltage compatibility (200V through 240V)

• Ambient temperature range: 5-40 degrees C (40-104 degrees F)

• Wide Tunnel Sealing Head

• Mounting Yoke

• Adjustable sealer mount accommodates a wide range of bottle heights

• Mobile Cart

• Automation I/O cable

• Plastic guide assembly

• Stalled bottle detection

1 New ECOCAP 2 Inline Spindle Cap Retorquer Including: 2 pairs of spindles each spring loaded with 2 pneumatic clutches. Stainless steel/anodized aluminum construction. DC variable speed drive. Standard switches with potentiometer. Dial indicators or rulers for quick change over. Manual height adjustment as standard. Air release valve. 208V 1Ph 60Hz.

SPECIFICATIONS: LEFT to RIGHT Flow Configuration. Bottle range from 1” to 6” diameter and from 1” to 12” tall. Cap range from 3/4” to 5” diameter. Double side guide belts, increased bottle stabilizing assembly. Required when unstable or tall and slender bottles are to be tightened. Safety interlocked lexan guarding

CSA Electrical Approval / Certification (Canadian Standards Association) UL recognized.

SANITARY CONVEYORS (Capper, Induction sealer and Cap Retorquer)

1 New 18 Ft DELTAVEYOR Raised Bed Stainless Steel 4" Tabletop Conveyor. 12 Gauge Stainless steel, threaded feet for height adjustment, 2” high raised bed for easy access for cleaning beneath Low friction table top flex chain 4’’wide. CSA Electrical Approval / Certification (Canadian Standards Association) UL recognized

1 New 48" Diameter DELTAFEED "SURGE" Turntable Cabinet style - Variable speed. Bottle gate. Closed frame clad in Stainless steel. Complete with Guide rails Feed Shelf and dead plate * 120 volt, 1 phase, 6 amps. CSA Electrical Approval / Certification (Canadian Standards Association) UL recognized.

1 New 12 Ft DELTAVEYOR Raised Bed Stainless Steel 4" Tabletop Conveyor . 12 Gauge stainless steel Stainless steel. Threaded feet for height adjustment. 2” high raised bed for easy access for cleaning beneath. Low friction table top flex chain 4’’wide. Adjustable guides and guide rails. Variable speed ½ HP motor with variable Speed control. 110volts/60Hz/1ph. Heavy duty Gearbox. 90° Raised Bed Curved conveyor section, 10cm (4½") wide. CSA Electrical Approval / Certification (Canadian Standards Association) UL recognized.

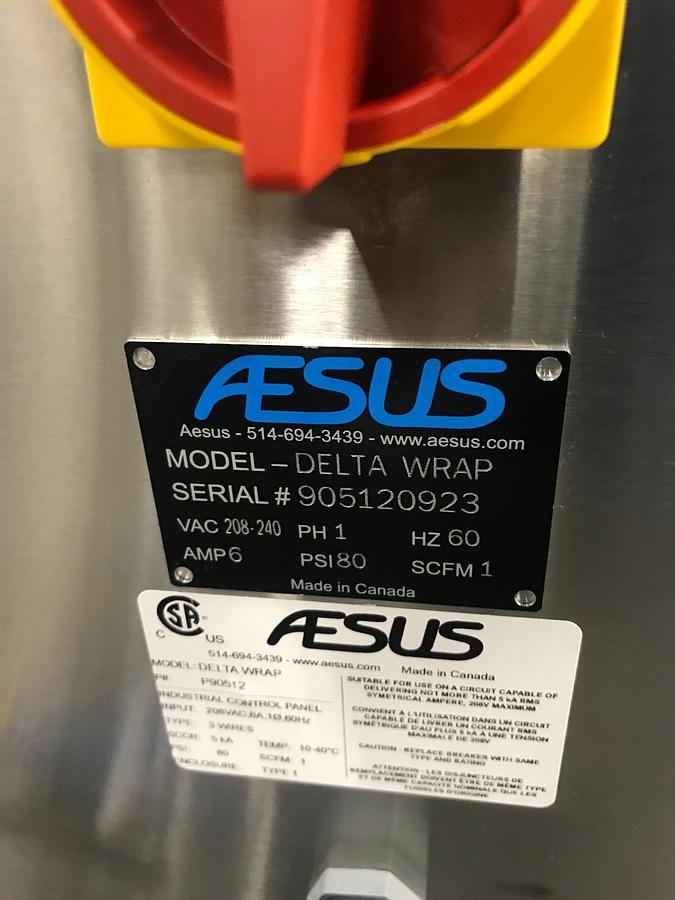

1 New Model DELTA WRAP Pressure sensitive labeler. Including SERVO Labeling applicator. The World’s most advanced Head with variable speed that can dispense over 50 meters/min! 9’ sanitary stainless raised bed conveyor x 4” wide with adjustable guide rails. Stainless steel cladded base cabinet with heavy duty frame and adjustable feet. Post mounted swivel Stainless steel control box. PLC: Allen Bradley MicroLogix 1400. Screen: Panelview Plus 6.5-inch, color. Product Separating wheel variable speed. Bottle Back up Sensor. Wrap around belt Standard size: 4’’ Tall x 12’’ Long. 11-1/2” diameter Label Reel holder. “Teachable” Label sensor CEON for transparent and other labels (includes metallic labels). Photoelectric product sensor. 208 Volts 1 Phase 60 cycles Standard Electrics. LEFT to RIGHT machine, includes left hand head.

Support plate (Heavy Duty) for label applicator when thermal transfer coder and / or vision camera or verification sensor is to be installed. Also needed for when Loose Loop, Power Unwind / Rewinds and / or weighted label rolls are installed. (includes anodized aluminum heavy stock plate and fine adjustment feature for UP / DOWN of label applicator).

CSA Electrical Approval / Certification (Canadian Standards Association) UL recognized.

· Beacon indication lights (red, yellow, green)

· Broken Web Detection (for 1 label head)

· Low Web Detection (for 1 label head)

· Reject station single bin (or shelf - please select) with pneumatic gate with confirmation (Requires PLC

1 New DOMINO model 230i+ Thermal Transfer Printer. Complete with 5" color touchscreen, mounting bracket and integration. (intermittent & continuous motion). Maximum Print Area: 32 x 55 mm (intermittent motion). Alpha Numeric, barcode and 2D matrix coding. Print Speed: 400 mm/s. Easy Ribbon replacement with this cassette version. No compressed air required Includes mounting bracket and Integration onto labeller.

1 New 60" Diameter DELTA ACCUMULATOR Turntable Stainless Cabinet style. Variable speed. Closed clad in Stainless steel. Complete with Guide rails and dead plate. 120 volt, 1 phase, 6 amps. CSA Electrical Approval / Certification (Canadian Standards Association) UL recognized.

Specifications

| Manufacturer | Aesus Packaging Systems and NJM Packaging Inc. |

| Model | Complete Packaging Line |

| Year | 2023 |

| Condition | New |

| Stock Number | 269 |

Disclaimer

The Equipment Kings, Inc. (“TEK”) makes reasonable efforts to provide accurate information and descriptions of the Equipment; however, TEK makes no representations or warranties, express or implied, as to the accuracy, completeness, condition, authenticity, provenance, attribution, genuineness, or value of the Equipment. All Equipment is sold on an AS-IS, WHERE-IS basis.